All Cast values

Casting the

best solutions

Overview

Die and tool making is a specialized field in manufacturing and engineering that involves the design and production of dies, molds, and tools used in various manufacturing processes. These tools are essential for shaping, cutting, forming, and assembling materials like metal, plastic, and composites into finished products.

Key Aspects

- Die Design and Fabrication: The process begins with meticulous die design and fabrication. These dies are typically made of high-quality steel and engineered to specifications. They consist of a stationary and movable half to create the desired part shape.

- Molten Metal Injection: Molten aluminum is injected into the die cavity at high pressure. This ensures that the metal fills the mold completely, taking on the precise shape of the die.

- Quality Control: Stringent quality control measures inspect the cast part. Visual inspections, precise measurements, and various testing methods ensure that the part meets the required standards and specifications.

Facilities

- High-Pressure Die Casting (HPDC)

- Low-Pressure Die Casting

- Gravity Die Casting

- Precision Machining

- Assemblies & Modules

Aluminium Gravity Die Castings

Aluminum gravity die castings, also known as permanent mold castings, is a metal casting process where molten aluminum is poured into a reusable steel mold. This method produces durable and high-quality aluminum parts with excellent dimensional accuracy, making it suitable for various industries, including automotive and industrial applications.

Aluminium Gravity Die Castings

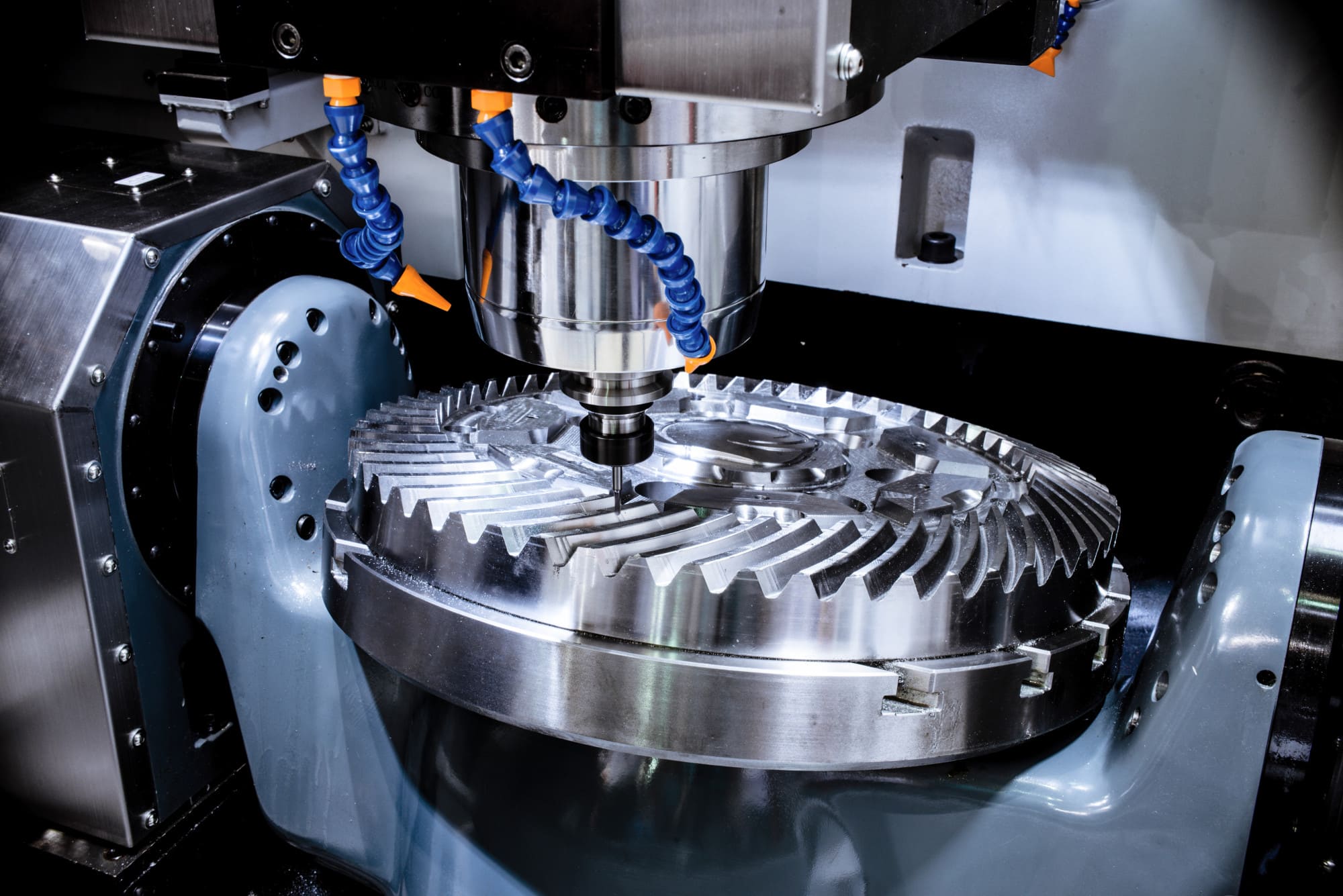

Die/Tool Making

Die/tool making is the process of designing, manufacturing, and maintaining specialized tools, molds, or dies used in various industrial manufacturing processes. These tools are crucial for shaping, cutting, or forming materials like metal, plastic, or composites with precision and consistency. Die/tool makers employ advanced engineering and machining techniques to create these custom tools, ensuring they meet exact specifications and quality standards.

Die/Tool Making

Machining workshop

A machining workshop is a specialized facility equipped with various machine tools and equipment designed for cutting, shaping, and finishing raw materials, often metals or plastics. Highly skilled machinists operate these machines to create precise, custom components and parts for various industries.

Machining workshop

Finishing Workshop

A finishing workshop is a dedicated facility where the final touches are applied to products or components, enhancing their appearance, durability, and functionality. This workshop specializes in processes such as painting, coating, polishing, sanding, or assembly, depending on the specific requirements of the project.

Finishing Workshop

Anodizing workshop

An anodizing workshop is a specialized facility that focuses on the anodization process, a surface treatment method primarily used for metal materials, especially aluminum. Anodizing involves electrochemically converting the outer layer of the metal into a protective, corrosion-resistant, and often decorative oxide coating.

Anodizing workshop

Who we are

Amwerk always gets the job done

Distinctively re-engineer revolutionary meta-services and premium architectures. Intrinsically incubate intuitive opportunities and real-time potentialities.

Choose your solutionsPayment plansPayment

More from AlankarMore services

Comprehensive engineering services: prototyping, structural design, electrical solutions, environmental assessments, and much more for your project's success.